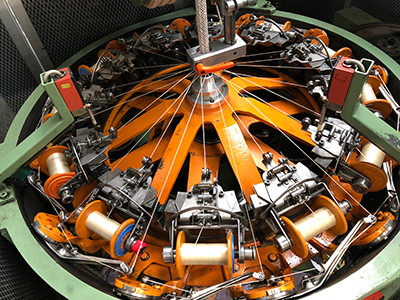

Wire braiding

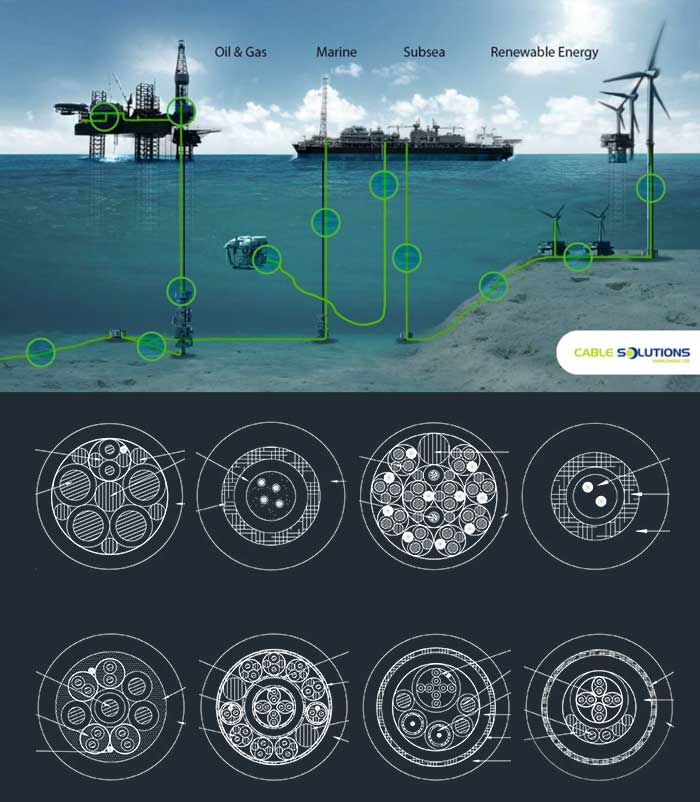

Cable design for various applications

Extensive manufacturing facility

23 / 08 / 2019

The oil and gas, marine, shipbuilding and renewable energy industries have specific bespoke cabling and connectivity requirements to ensure high levels of productivity and durability in harsh offshore environments.

The last quarter was especially busy for Cable Solutions, we undertook bespoke cable design and manufacture for a variety of subsea projects, with production runs of 300 to 5000mtrs. We were active in fibre optic cable manufacture, supporting projects with more efficient communication and seafloor monitoring. The advantages of using fibre optic cables in a subsea environment are well known, with operators leveraging the advantages of improved performance. We are able to design and manufacture smaller, lighter fibre optic and hybrid cables for subsea projects, offering large bandwidth in a compact configuration.

We have also been involved in the design and manufacture of subsea power cables and umbilicals for pumps and processing, including cables for terminating subsea trees, for energy, control and safety.

Graham Ross - Business Development Manager commented - "We are always ready to discuss cable design requests, and provide short manufactured lengths for project trials. Bespoke cable design and manufacture is one of our key strengths, and it's an area of our business that we are very competitive in."